Select Your Industry

← Back- Natural Resources

- Manufacturing

- Transport & Logistics

- Construction

- Engineering Services

- Healthcare

Select a Use Case

← Back- Select your Industry first

Skip for now

Who rely on Tiikr to build, manage, execute, and audit critical operational processes every day.

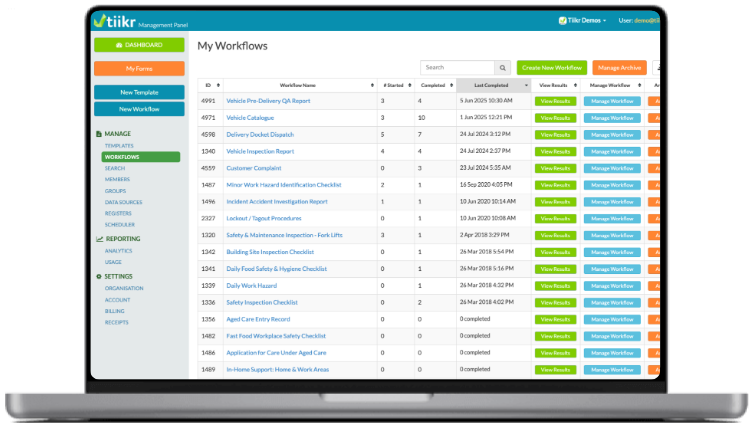

Tiikr is a mobile forms and workflow automation solution that is designed for industrial, manufacturing, and distributed field operations.

Level 18, 324 Queens Street, Brisbane, Queensland, Australia, 4000

© 2014-2026 Tiikr | All Rights Reserved.